Looking to buy the best 3D printer for your hard-earned money? Having trouble figuring out where to start and what to buy? We understand your struggle. To help you speed things up we’ve put together a comprehensive guide and a list of our top picks for best 3d printers.

You’ve probably heard many awesome things about 3D printers and what you can build with them. There are so many wonderful models out there that can make your builder’s dreams come true. But if you want to buy a 3D printer, which model will best suit your needs? How much should you spend? Here’s a guide on how to buy a 3D printer that will best suit your needs.

CONTENTS:

- Before you buy: a guide to purchasing your first 3D printer

- 3 Best 3D Printers

- What are 3D printers? What are they used for? What are their advantages and disadvantages?

- How we choose these products

Before You Buy: A Guide to Purchasing Your First 3D Printer

So, before you even start looking around for a 3D printer, first, we advise you think about what and how often you want to 3D print:

- If you are just eager to try out the technology, we advise you visit a local Fablab or a Makerspace. 3D printers are expensive and also have a very steep learning curve, and the people working at those places will help you get up to speed. You will also save yourself a lot of time and, most importantly, money.

- If you just need a single part printed once a month, there’s no need for you to opt in for a 3D printer. It is immeasurably cheaper to use one of many 3D printing services.

If you don’t fall into one of these two categories, then you are a prime candidate to buy a 3D printer.

What Type of Printer Should You Go For?

At this moment, there are nine major 3D printing technologies. And as you probably don’t want to shell out 500.000 dollars on a metal 3D printer, you are left with two consumer 3D printer types. These two types are Fused Deposition Modeling (FDM) and Stereolithography (SLA).

Option 1: FMD 3D Printers

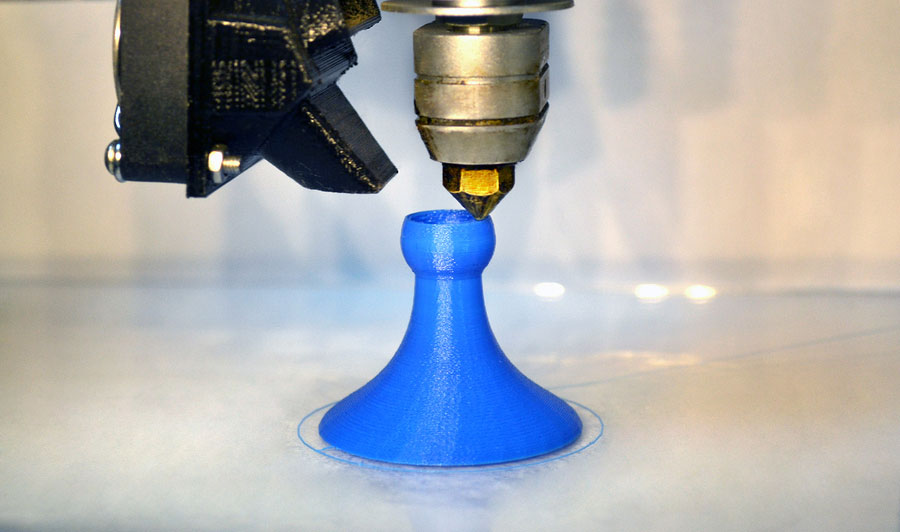

Fused Deposition Modeling is the most common 3D printing method used in desktop 3D printing. They are the least expensive option you have and are an excellent choice if you’re a hobbyist or an enthusiast. They work by first heating and then extruding a thermoplastic filament to create the part – one layer at the time. After each print cycle, the printing table (also known as the print plate) lowers the object ever so slightly to allow for the next layer to go on top. The 3D printer will repeat this process until the object reaches its finished height. Objects that have overhangs require support structures or materials in order to fortify the build process. Of course, this process is a bit more complex than that, but this is the bare basics of how FMD 3D printing method works.

From a buyers perspective, the choices can be a bit overwhelming at first. After all, there are over 50 companies offering 3D printers that utilize the FMD method. The prices can range from just a couple of hundred bucks to several thousand. Because of this, it really pays out to go through our guide, so that you can narrow down your choices. You will have the required knowledge to zoom in on those models that match your budget and your expectations. Thankfully, the most expensive part of a 3D printer is the 3D printer itself, the filament rolls are reasonably inexpensive. This technology is forever going forward which means that newer, more improved models will continue to appear every now or so.

FMD 3D printers represent a cost-effective mean of product development and rapid prototyping. They are very popular in small business and education sectors because they are capable of fabricating robust parts quickly and reliably. They are also quite versatile material-wise because the thermo element comes in many variations.

Option 2: Stereolithography (SLA) 3D Printers

Stereolithography 3D printers are another good choice for beginners, though they work in a different way. SLA is an expressly versatile technology. The way it works is by exposing layers of photosensitive resins to an ultraviolet laser beam. In more simple terms the process begins with liquid plastic. This plastic then cools down to a solid form which eventually produces the hardened 3D objects. Similar to FDM printing, the printer moves down by the exact thickness of a layer after each print cycle. Each layer goes on top of the previous one until the model is completely printed. Just like FDM printing, SLA 3D printing also requires support structures when printing objects that have an overhang. The end product, because of the nature of printing material, needs some rinsing and (in some cases) needs baking in a UV oven to complete the process.

The choice between an FDM and an SLA printer is quite straightforward. It all boils down to costs and quality. If you need high precision and an ultra-smooth finish, go for an SLA 3D printer if the price is not an issue for you. If you’re on a thither budget and precision is not important, then you’d want to look at your best options available in FDM printers.

Which type of 3D printer will meet your expectations?

This seems like a simple question, right? But if you overlook it you are risking throwing your money away and ending up disappointed. Keep in mind, not all 3D printers are created equal. This applies to both machines as well as technologies. Imagine getting yourself a brand new 3D printer, getting it home, only to discover it’s too small for your needs, or that the quality of the print is substandard. The cost doesn’t just end at the device either, you also have to consider support structures and printing material.

Most beginners will not be expecting to print large objects with intricate details, but some of them will. If you want to sell your services to other people, then high-quality prints will more likely be a priority. In this case, you will want to focus on two important factors:

- Print resolution – The smaller the better

- Print speed – which typically includes 40-50 millimeters per second, and 150 millimeters per second.

There are a number of great 3D printers for sale these days. The thing you should be careful with is the price. In the budget price range, there might not be all that much difference between a 350 dollar model and the one that costs 600 dollars. A more expensive device doesn’t always translate to higher quality, at least not to the human eye. Because of this, you need to know what you want to 3D print specifically and look for a printer that can manage it.

Print Speed

It’s natural to think that faster is better. However, it all depends what you expect from the object you’re printing. It’s important to keep in mind that the faster a 3D printer prints, the lower the output quality will be. It is very important not let print speeds impress you too much at the buying stage. You should particularly be cautious with printers that boast print speeds over 150 millimeters per second. Once you figure out what type of parts you plan to print, then you can determine which printing speed best suits your needs. Slower speeds are always going to be the better option, at least for larger, high-quality objects.

Please note that 3D printing is not a hobby or an occupation for those who lack patience. Once the machine is set up and running, just let it be. In other words, leave the room and come back later, much, much later with some projects preferably. To ask the question “how long does it take to 3D print an object” is similar to asking how long a piece of string is. It takes as long as it takes. The size and the complexity of the object you’re printing plays a major role in print speed. The layer height you choose is another factor that affects it. If you print at a higher resolution, you can expect to wait longer, but the reward is a high-quality 3D printed object. As you might have gathered, it’s impossible to give an average time, which could be anything from just a couple of minutes to several hours, depending on the above.

Think about what are your ultimate goals with 3D printing

If you’re absolutely sure you want to invest in a 3D printer, pause for thought first. Think about what are your ultimate goals before making a decision to buy one. You wouldn’t buy a tiny sports car if you just got married and planning on starting a family right away. Likewise, you don’t want to invest your money in a small, budget 3D desktop printer if you have high ambitions. It would mean your first printer will soon become obsolete, and therefore a waste of money. Ask yourself this before committing: Do I want to design and print bigger and better things as soon as I gain more experience and will I experiment with other materials and print multiple colored objects?

Depending on your answer, you will be able to narrow down your choices considerably.

Printing Materials

3D printing technologies have come a really long way since their inception. Not only are the machines more advanced, but also the types and ranges of materials used. So what type of materials should you 3D print with? That all depends on what you want to print and what’s your end goal. Not all 3D printers can print with every type of material. Most of you reading this guide, have no interest in industrial 3D printers. You are more likely focused on consumer-oriented models, AKA desktop 3D printers. These type of 3D printers typically use a thermoplastic filament. You can find all of them online, in a wide range of diameters, lengths, and colors.

Here are some of the most popular materials used for desktop 3D printers:

- Acrylonitrile Butadiene Styrene – or ABS for short, is a great material for kitchen appliances, musical instruments, and toys. Lego bricks are made out of this material.

- Polyvinyl Alcohol – or PVA for short, is a special type of water-soluble plastic. You can find this material in the paper adhesive, various types of packaging, hygiene products, and in children’s putty. This material is also used in fishing bait containers because PVA dissolves underwater, therefore releasing the bait to attract nearby fish. When it comes to 3D printing, PVA is commonly used to provide support structures to 3D objects during the build process.

- Polylactic Acid – or PLA for short, is an environmentally friendly material that’s beneficial for a range of uses. You can find this material in anything from surgical implants to food packaging, disposable garments (baby diapers for example), and lots of other products,

Each of these materials has their own advantages and disadvantages. What type you choose will depend on your 3D printed model. Once you know what you intend to 3D print, then you can explore the best material for the job. Before you even order the materials, you first have to check your printer to see what the filament diameter is. You could have a printer that accepts both 1.75mm and 3mm filaments. Most models on the market don’t accept both sizes, so be sure to check before ordering.

You can find these materials online. They are most often available in different weights, with options of spools in 750gm, 1kg or 2.kg.

Print Bed

3D print beds come in two options: heated and non-heated. The bed is paramount to the outcome of your 3D printed object as it’s what holds the object steady from the start of the process. To keep the object from moving during the printing, you have to adhere it to the 3D printer bed before the progress begins. There are two ways to do this, you can either use glue or you can preheat the print bed. If you decide to use ABS filament, a heated bed is a must. PLA filament is more flexible though, and you can use both heat and adhesive.

Open or Closed Frame 3D Printer?

The final question you should ask yourself when purchasing the best 3D printer for your needs is should you chose an open frame or a closed frame model? Both of these have their pros and cons, so let’s take a look at these now!

An open frame 3D printer is, as its name suggests, more exposed. This can be very convenient because it gives you easy visibility of an active printing process. It also allows for quick access to the printer bed and the extruder. On first glance, this seems like the most convenient setup, but you have to consider a few downsides. Let’s take a look at why closed frame arrangement is a better option for some people.

Closed frame 3D printers feature a fully enclosed structure. This means that it has a door, walls, and a lid of some description. The most important thing you should note about closed frame printers is that they are safer, period. The safety aspect is certainly worth factoring in if you have kids or pets (or both) in the house. You don’t want them to accidentally burn themselves by touching the exposed extruder. These type of 3D printers also help reduce odors, which you’ll certainly be thankful for if you decide to print with ABS. After a short period of time, the burning plastic smell will become overwhelming, especially in poorly ventilated rooms. Another advantage of closed frame 3D printers is that they tend to be quieter. Any reduction in printing noise is welcome if you’re working in the same room where you keep your 3D printer. Ultimately, closed frame 3D printers can often maintain temperature more smoothly.

3 Best 3D Printers

There are all kinds of things to consider before opting in for a 3D printer, especially if it’s your first one. If you’ve read through our guide from top to bottom, you should now have a good basic idea of what to look for. To make things easier for you, we’ve prepared this list of the best 3D printers on the market. We’ve given our best at showcasing you models that are both beginner friendly and offer decent prints speeds and resolution.

So, let’s jump into our little countdown of the best 3D printers.

1. Elegoo Mars Pro 3D Printer

Elegoo Mars Pro is one of the most popular 3D printers. It is popular among users for different obvious reasons. It is relatively light, with a weight of 7.5kg. The printer size is 7.87in (L)×7.87in (W)×16.14in (H)

The printer has a rubber seal at the bottom that prevents the odor of the resin from leaking out. What the rubber seal does is reduce loud noise while the machine is printing. Unlike other printers, the USB port is located at the front for easy access.

The matrix light source of this printing machine comprises 28 50Watt UV LED lights that have parallel light patterns. These patterns ensure excellent printing results and precise printing size. The layer exposure time is also reduced by 25%.

It has an anti-slip hexagon socket screw that helps with stability and long-lasting results. It is designed with a resin vat made with aluminum. This design offers both sturdiness and elegance.

The printing machine has a built-in activated carbon filter that assists in absorbing and filtering resin odor before going through the ventilation system. User experience is enhanced by taking in fresh air while printing.

This printing machine is the first resin-dependent 3D printer to use a sliced file of cab configuration. This configuration reduces document size by almost 90%.

Pros

- Higher precision and excellent performance

- Light and convenient to use: With a weight of 7.5kg, you can move with it from one place to the other

- Anti-slip hexagon socket screw

- Budget-friendly: You don’t have to break the bank to get yourself one.

Cons

- It doesn’t come with a sample bottle of resin.

Bottom Line

From the customer’s reviews, we observed this product is hugely popular among users. One of the factors that made it popular is the low price. The product offers great value for money. If you are on a tight budget, we highly recommend this product. It is perfect for both beginners and experienced 3D printing enthusiasts. This 3D printer lives up to customers’ reviews as one of the best in the market.

2. LulzBot Mini 2 Desktop 3D Printer – Best Intermediate 3D Printer

Released quite some time ago, the LulzBot Mini competitive price made it attractive to home users who are looking for a printer that can utilize multiple materials. The LulzBot Mini hits the sweet spot in those who have spent some time in 3D printing world and are looking for a midrange model that will serve them for many years.

The Mini 2 shares some design aspects with the original Mini, putting the focus on printing rather than aesthetics. We’re in no way saying that this is an ugly printer, quite the contrary, the anodized aluminum frame and 3D printed parts give the Mini 2 a clean and functional look.

There is another reason to the printer’s functional look. Most of the upgrades are on the inside. These include a more flexible print head than one in the Mini 1, faster motors, and a new large modular print bed.

The print head on the Mini 2 uses an E3D Titan Aero nozzle and an upgraded feeding mechanism, which means it can handle flexible materials like Ninjaflex. Previous model couldn’t handle these type of materials and required an upgrade if you wanted to use them.

The modular print bed on this mid-range 3D printer is designed to accommodate for most printing materials. Some materials like the PLA stick best to a heated print bed coated with sticky plastic, while others stick best to a plain glass surface. The LulzBot Mini 2 offers both. You can take out the 6.3 x 6.3 inch print bed and flip it over. One side is coated with PEI plastic, while other side features a glass surface. It can also be heated to 120 degrees Celsius, which means it will work perfectly with materials that stick better to a heated print bed.

You can control this 3D printer either via an LCD screen located on the chassis or via the free LulzBot edition of Cura. You can control the printers function by turning the knob below the LCD screen. You can load filament, set temperatures or even print file from the SD card by only using the inbuilt controls. This means you can use the Mini 2 as a stand-alone device.

The printing process is very quiet, with the device making only low squeaking noise as the print head moved around. The printing speed is just as impressive, with a printing time of only 3 hours for a 4.5 inch object. The print quality is unbelievably good thanks to the print head. You will have no trouble with both smooth and sharp objects.

Pros

- Excellent print quality

- Excellent print speed

- You can use multiple printing materials

Cons

- Printing with squishy materials produces a lot of whiskering

Bottom Line

The LulzBot Mini 2 is a successful upgrade of the original Mini. It’s fast, flexible and produces high-quality prints with both ABS and PLA filaments. This 3D printers is a godsend to those who are planning on taking a deep dive in the 3D printing world. Mid-range 3D printers that are able to print using multiple materials at reasonable speed are far and few between, which makes the Mini 2 worth every cent.

3. Anycubic Photon Mono 3D Printer

This is one of the best 3D printers you would find in the technology market. The product is a real definition of a modern 3D printer. This product is relatively light, with a net weight of 4.25kg. The size of the printer is 227mm(L)×222mm(W)×383.6mm(H)

One of the standout features of this product is the printing speed. It is 2.5 times faster than its predecessor; the Anycubic photon. The quick prototyping of this product has greatly enhanced the printing speed and efficiency.

Another feature of this product that caught our attention is the 6.08″ Monochrome LCD with a 2K HD resolution that comes with it. You may be surprised it takes only 1.5 seconds per one layer of exposure for this 3D printer to cure the resin.

The LCD screen makes use of the matrix parallel light source. This feature ensures better heat dissipation and improved printing precision. The printer has a sealed gasket that helps guard against resin leaking into the machine.

Pros

- UV-blocking top cover: with this feature, you don’t have to worry about UV rays damaging your eyes. The UV top cover blocks about 99.95% of ultraviolet rays.

- Top cover detection: the printer is designed in a way that you can stop printing instantly after removing the top cover. It is easy to find your mistake without wasting resin.

- It is is lightweight: unlike other printers, you can move this printer with ease from one place to the other without stress.

- Superb print quality when compared to other printers.

Cons

- The build plate size is small. Not recommended for large projects.

- It has no extra resin included.

Bottom Line

Anycubic Photon Mono 3D is a great printer to have. It’s very easy and friendly to use. You can set up the whole printer for use in less than 20 minutes. The instructions are very simple and easy to understand. The printer has everything you need to get it started. We would highly recommend this printer, especially to those who are new to 3D printing.

What are 3D printers? What are they used for? What are their advantages and disadvantages?

For the uninitiated, 3D printing is the automated process of building a three-dimensional object by applying material rather than taking material away (drilling, machining, etc.). 3D printing isn’t a new concept, a process called additive manufacturing was introduced back in the late 1980s.

Charles Hull, the co-founder of 3D Systems, had a patent issued for a stereolithography system in 1988. The same year 3D Systems sold its first industrial 3D printer that utilized 3D printing. Shorty after, 3D printing was first commercially used as a method for fast prototyping.

The 1990s was a period when 3D printing really took off with many industrial 3D printing companies being founded. Each new company tried (and in many cases, succeed) to come up with newly invented processes. Of all these companies, only three are still on the market.

Fast forward to 2009 and 3D printing has finally become commercially available to the common folk. The main culprit for this 3D printing explosion was the RepRap open source project. They utilized the Fused Deposition Modeling (FMD for short) technology which involves thermoplastic material getting heated and extruded through a nozzle. This nozzle deposits molten material layer by layer onto a build platform with each layer sticking to the one beneath it.

Since then, new and other companies started innovating, creating and improving the consumer 3D printer technology to the point where we have both affordable low-end, and expensive high-end printers utilizing the FMD technology and others which are going to be mentioned a bit later.

Nowadays you can find a 3D printer for around a hundred bucks. We’re not saying that these affordable models work wonders, but they’re the best 3D printers for small objects like pen casings or custom parts for miniatures (if you’re into modeling).

So, what is 3D printing good for? Well, whether you need a frame for your latest drone project, a simple door stopper or anything else in between, you can 3D print it. 3D printing is awesome for making your life easier because it allows you to print simple “lifehack” objects. As of the time this article is written, there are around 3 million 3D print files you can find in various 3D repositories.

On the more serious industrial part of things, 3D printing has enabled things never before possible and accelerated product development. Almost every industry benefited from this technology, from healthcare to the automotive industry.

One spectacular area where 3D printing excels is in the healthcare industry. Custom built prostheses, and 3D printed tissues are becoming more common in laboratories around the world.

Not only that, but 3D printing is extremely useful when it comes manufacturing small batches of goods. For instance, the aerospace industries print small jet engine components with complex inner channeling, making the engine more fuel efficient. This would have never been possible with the CNC milling method.

Like many emerging industries, 3D printers offer many benefits in a wide spectrum of areas. Some of these include improvements in financial, logistical, healthcare, as well as creative and environmental areas.

This technology allows for endless customization with regards to design and material. Like we mentioned before, 3D printing introduced a revolution in the healthcare sector because it made prosthetics so affordable. Complex prosthetic limbs can be manufactured precisely to individual needs for a fraction of the cost.

In the aerospace industry, complex parts that take a long time to produce or assemble can now be 3D printed. This speeds up the production and assembly time immeasurably and reduces the cost of the final product. Not only that, but some components that were impossible to mass produce are now getting mass produced.

3D printing has also enabled designers to rapidly prototype products, ultimately saving time in the design process. This revolutionary technology has allowed new or improved products to hit the market much sooner than with conventional means and methods.

One of the awesome things about 3D printers is that they are portable. This allows end products or components to be printed where and when they are required. In many cases, this lowers inventory needs. For example, satellites will most likely be 3D printed in Earth’s orbit in the future. Sounds exciting right?

Because these printers utilize the concept of adding material rather than subtracting material, the printing process leaves little to no waste. Even though materials used in conventional CNC machining are recyclable, the process of recycling material cost. Just imagine how much money could be saved with 3D printing.

What 3D printing can’t do?

Even though 3D printing is deeply implemented in the world of prototyping, it is still quite a few years away from having a real breakthrough in the world of manufacturing. Once this technology finally makes this breakthrough, it will allow it to spread from more than just prototyping, with the exception of select components already being manufactured by 3D printers.

The main thing keeping this from happening sooner is the relatively long time it takes to 3D print something that can just as well be manufactured using traditional methods.

Another thing that limits 3D printers is their size. The size of a 3D printed object is only limited by the printer’s size. Although there are some pretty big models out there that print with cement, for example, high-quality parts that require extreme precision are limited to smaller machines which can also be quite expensive depending on what they’re designed for.

Another thing that limits this technology is that it can only print in one material at a time. Even though multi-material 3D printers do exist, they are both uncommon and cost a small fortune.

How We Choose These Products

When compiling the list of products above we were mainly focusing on showcasing devices that offer excellent print quality for their price range. Because these devices range in price and quality, we focused on reviewing models that will best suit beginners as well as enthusiasts. We also gave our best at picking models that are of high-quality and will last you for at least a couple of years.

So what do you think about 3D printing? Will it become even more popular in the future? Leave us your thoughts down in the comment section.

No Responses