Best 3D Printers in 2025: Expert Buying Guide, Top Picks & Trends

Updated October 2025

Tested by Morgan Blake

Quick Comparison: Best 3D Printers 2025

| Model | Type | Build Volume | Why it wins |

|---|---|---|---|

| Bambu Lab X1 Carbon | FDM CoreXY (enclosed) | 256 × 256 × 256 mm | Fast + polished profiles; reliable multi-material (AMS); excellent PETG/ASA surfaces. |

| Creality K1 Max | FDM CoreXY | 300 × 300 × 300 mm | Large cube volume; quick motion; LiDAR leveling + AI monitoring help new users. |

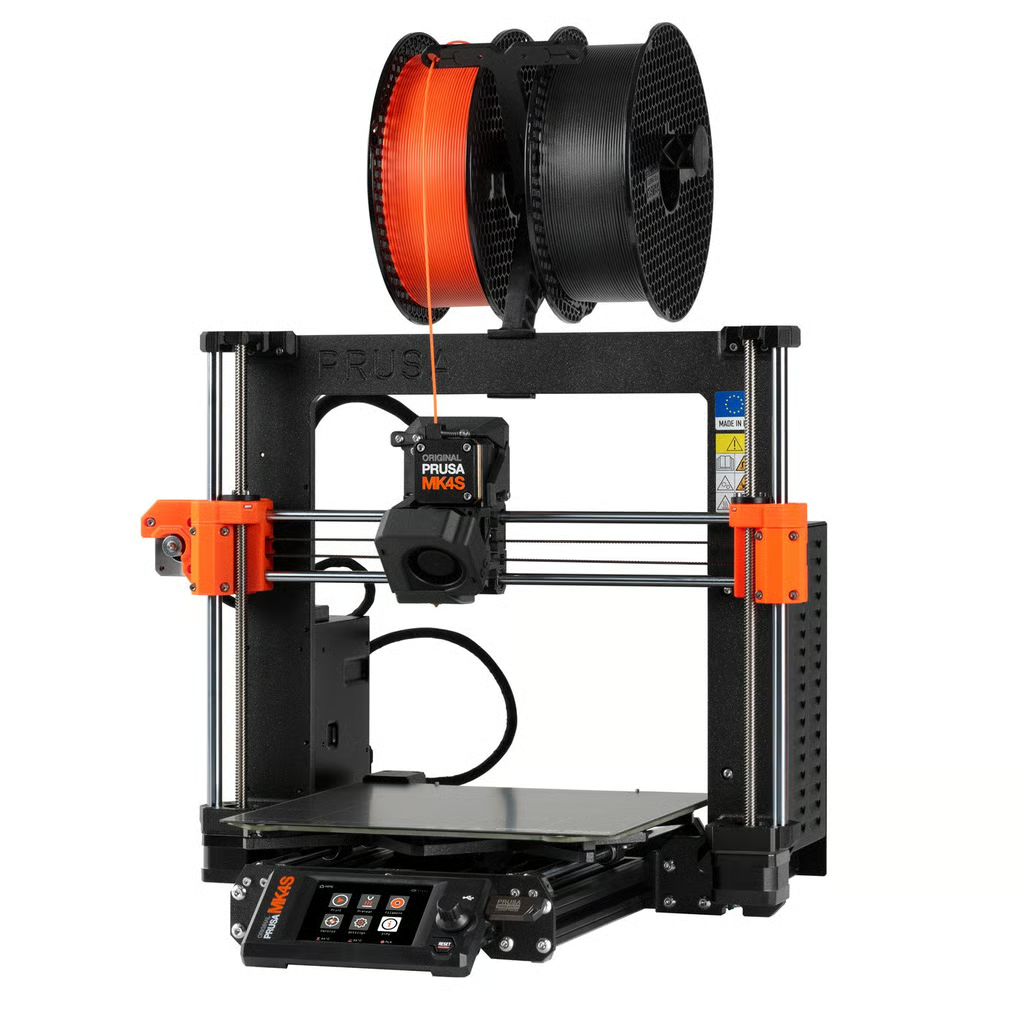

| Prusa MK4 | FDM bedslinger | 250 × 210 × 220 mm | Open-source ecosystem, stable profiles, spares and documentation for classrooms. |

| Elegoo Mars 4 Ultra 9K | MSLA Resin | ~153 × 77 × 165 mm | Micro-detail for minis/jewelry; sharp edges and crisp text. |

| Anycubic Photon Mono 2 | MSLA Resin | ~165 × 89 × 143 mm | Great entry price with sane learning curve. |

Before You Buy: What to Know in 2025

- Try first: if you only want to experiment with 3D printing, use a Makerspace or print service.

- Print frequency: occasional prints can be outsourced; weekly printing—owning pays off.

- Budget realistically: plan for filament, nozzles, build plates, filters, and post-processing.

Good news: Reliable starters under $300–$500 now deliver quality that used to cost $1,000+. See Best 3D Printers Under $500 and our Under $300 picks.

Types of 3D Printers (FDM vs. Resin)

FDM (Fused Deposition Modeling)

FDM melts filament and lays it down layer by layer. CoreXY with input shaping is the 2025 sweet spot for speed without ringing. For most makers, FDM is the best first printer—especially for bigger, functional parts. If you’re deal-hunting, track our Black Friday 3D printer deals.

Resin (SLA / MSLA)

Resin cures liquid photopolymer with UV for incredible detail. It needs PPE, ventilation, and wash/cure steps. For minis, see our miniatures guide.

3D Printing Materials: What to Use & Why

- PLA: easy, smooth finish; décor, jigs, prototypes.

- PETG: tougher, heat-resistant; great for enclosures and mounts.

- PCTG: less brittle PETG alternative; nice for translucent parts.

- ABS/ASA: stronger, higher temp; needs enclosure; ASA resists UV.

- Nylon/PA-CF: very strong; requires hardened nozzles and dry box.

- Resins: standard, tough, flexible, castable blends.

Deep dive: Filament Buyer’s Guide.

UX note: PETG and ASA have been our best performers for smart-home and pet-area prints that see moisture, heat, and cleaning. Print feeder risers, spill guards, camera plates, and cable covers with rounded edges and low-porosity infill for sanitation. For automations, see Best Smart Pet Feeders and Best Pet Cameras With Treat & Night Vision to match dimensions before designing mounts.

Key Features That Actually Matter

- Motion system: CoreXY + input shaping = speed with clean walls.

- Enclosure: stabilizes ABS/ASA and cuts noise/odor.

- Auto-leveling: one-tap Z-offset and flow calibration reduce tinkering.

- Extruder/nozzle: direct-drive for flexibles; hardened tips for CF.

- Build volume: size for 90% of planned prints; bigger beds cost time and power.

- AI cameras: remote monitoring and fail detection can save long jobs.

Our Top Picks for the Best 3D Printers of 2025

Enclosed CoreXY with mature profiles, input shaping, and optional AMS. In our PETG tests, we hit clean 0.2 mm walls at ~220–250 mm/s without ringing. ASA parts showed consistent layer bonding with the enclosure closed. AMS swaps were reliable across four colors. For maintenance and profiles, see the Bambu documentation.

- Fast prints with clean walls

- Consistent first layers and flow

- AMS enables multi-color/material

- Quiet operation when enclosed

- Ecosystem approach; limited mod path

Next steps: Upgrades that matter · Calibration guide

Roomy 300 mm cube, quick motion, and LiDAR-assisted leveling. After an initial flow/pressure advance tune, our cosplay prop shells needed less sanding than expected. AI monitoring caught a lifted corner at 3% progress and paused correctly. For setup nuances, see the K-series support page.

- Large build volume

- Fast CoreXY motion

- AI camera + LiDAR assists

- Firmware polish varies by batch

Beloved in schools and labs for bulletproof profiles and spares. Our classroom trial saw consistent PLA and PETG results with minimal babysitting. Not the outright speed champ, but the fewest surprises. Official maintenance and profile notes live in the Prusa Knowledge Base.

- Trusted ecosystem and support

- Great documentation

- Predictable surfaces in PLA/PETG

- Slower than top CoreXY picks

Durable frame and modular toolheads. In a shared-lab test, Wi-Fi control and easy parts sourcing simplified oversight across multiple classes. Smaller bed than K1 Max, but maintenance is straightforward. LulzBot’s OHAI guides are useful for teachers and lab admins.

- Serviceable and sturdy

- Modular toolhead options

- Modest build volume

Compact footprint with polished setup. Our beginner tester went from unbox to first clean PLA print in under an hour following on-screen prompts. Pair with the Beginner FAQ to flatten the curve.

- Low-cost entry

- Fast onboarding

- Good community tips

- Less headroom for huge builds

We printed 28–35 mm minis with crisp text and armor lines. Plan for a wash/cure station, nitrile gloves, and ventilation. Great choice for jewelry masters and display pieces. Elegoo’s downloads & guides help with exposure presets and firmware.

- 9K detail and sharp edges

- Excellent for minis/jewelry

- Resin handling + PPE required

Compact and affordable. With proper supports and exposure, we got clean minis and trinkets. Budget for resin, IPA (or water-washable resin), and UV cure.

- Low entry cost

- Strong results for the price

- Small build volume

If you plan to sell prints, read Profitable 3D Printing Business Ideas. When you’re ready to tune harder, try Klipper & input shaping.

VR crossover: A printer turns your VR room into a customizable lab. Start with essentials from Best VR Accessories, then print cable anchors, lens covers, or wall hooks. If you’re building a dedicated play space, our VR Room Buying Guide covers layout and cable management so printed parts solve actual problems.

Setup, Safety, and Maintenance

Ventilation & Filters

ABS/ASA benefit from an enclosure and filtration. Resin printing requires gloves, eye protection, and a wash/cure routine. Follow local waste rules.

First Layer Success

- Clean plates with IPA; keep finger oils off surfaces.

- Re-run leveling after transport or long downtime.

- Test a small square for adhesion and flow.

Maintenance Basics

- Keep belts tensioned and rails clean.

- Swap worn nozzles—faster with abrasives.

- Update firmware and slicer profiles regularly.

See Upgrades That Actually Matter for shrouds, hardened nozzles, and surfaces.

Smart home angle: 3D printing quietly levels up a smart house. Diffusers, wire clips, and sensor mounts can be tailored to your trim and hardware. For lighting accuracy, compare ecosystems in Best Smart Bulbs. For HVAC, pair printed brackets with features in Best Smart Thermostats.

The Future of 3D Printing

Expect better QC from AI vision, more closed-loop extrusion, and faster toolpaths that maintain surface finish. Filament blends will push heat and impact strength. Industrial adoption keeps expanding across aerospace, dental, and healthcare.

FAQ

Should beginners start with FDM or resin?

FDM for most—cleaner, cheaper to run, and better for larger practical parts. Resin excels for minis/jewelry but needs PPE plus wash/cure.

How fast is realistic in 2025?

Clean results around 200–300 mm/s are common on tuned CoreXY systems. “600 mm/s” marketing needs ideal tuning and stiff mechanics.

What build volume should I choose?

Plan for your largest expected project with ~20% margin. Larger beds take longer to heat and draw more power.

Is an enclosure worth it?

Yes for ABS/ASA (bonding, odor, noise). Optional for PLA.